检测设备

尼兰德致力于在先进的高科技试验机的帮助下,为客户不断提供满足需求或超越预期的优质产品和服务。

Digital Projector

Digital Projector is to measure the goods size precisely.Different from manual operation, digital projector can automatically position the lens then through CCD sensitization change to digital signal, refer to the grade criteria to judge imaging quality.

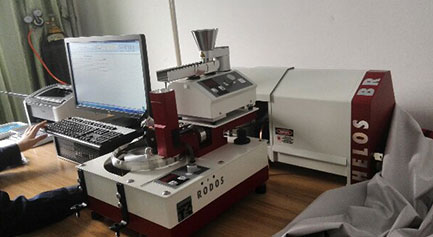

Sympatec Laser particle size analyses

Laser particle size analyses offers a powerful technology for particle size distribution analysis of powders, control every batch magnet property in the best condition.

Oven

Oven can do aging test with different magnet grades, temperature can be from nomal to 400℃.

Kanetec Tesla Meter

To test the finished magnet surface gauss, measurement range is 0-2000mT.

Thickness Tester

Confirm the coating thickness based on the corrossion degree by electrolyte, at present can test Zinc, Copper, Ni-Cu-Ni.

Magnetic Demagnetization Tester

To test the rough magnet property after sintering process, measuring range of BJ is ±1.999T, H access range is ±3999KA/M, (BH)max range is 1-80MGOe, also capable of the variable temperature testing function from nomal temp to 200℃.

Fluxmeter

Multi-position choice of the measurement range, applied scope 0-160mwb.

Magnetic Declination Tester

Test magnetic flux through triaxial coil: Φx(magnetic declination), Φy(magnetic moment), Φz(magnetic flux), then caculate three directions’s magnetic moment: MX/ MY/ MZ, total product’s moment is M.

Bearing Measurement instrument

Measure kinds of bearings run-out tolerance. This instrument is very easy to practise with high efficiency.

Hardmeter

To measure the metal hardness.Use impact part to knock the sample surface, measure the knock speed and rebound speed specific value at 1mm away sample surface of impact part.HL=1000×VB/VA

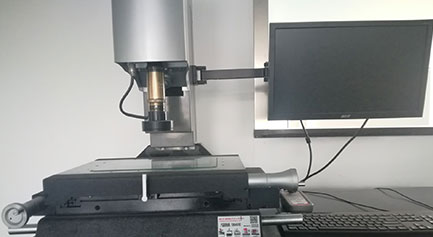

Coordinate measuring machine

Precision Measuring Instrument.Coordinate measuring machine, brand Explorer Classic10.15.08.On a workbench (large and giant) capable of placing workpieces, the probes in three mutually perpendicular directions are moved manually or maneuvered to the point to be measured, and are read by the reading device and the digital display device, so it is a measuring device displaying the coordinate values of the measuring points. The probe includes a guiding mechanism, a length measuring element, and a digital display device. Obviously this is the simplest and most primitive measuring machine, with this measuring machine, the coordinates of any point in the measuring volume can be displayed by the reading device and the digital display device.The collection and transmission device of this measuring machine is probe, which is equipped with a grating scale and a reading head in the direction of the three axes of X, Y and Z. The measurement process is that when the probe contacts the workpiece and sends a signal of the sampling point, the control system collects the coordinate value of the current machine three-axis coordinate relative to the machine origin, and then the data is processed by the computer system.